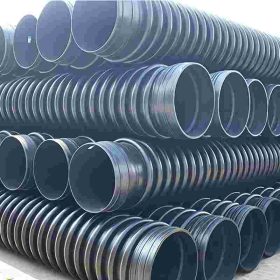

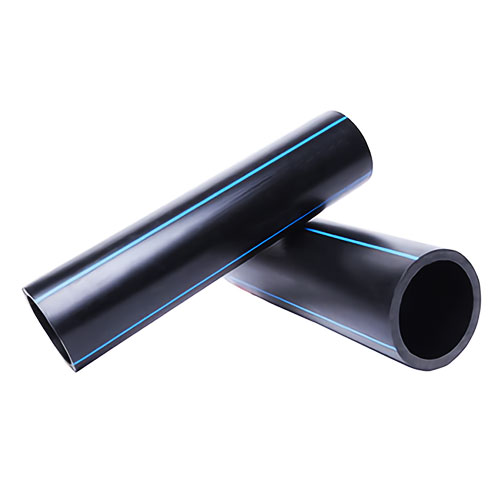

HDPE Wrapped Structural Wall Reinforced Pipes represent a cutting-edge solution for various infrastructure needs, combining the strength of reinforced materials with the durability of high-density polyethylene (HDPE).

Performance of HDPE Wrapped Structural Wall Reinforced Pipes

Structural Reinforcement: The pipes feature a reinforced structural wall, enhancing strength and providing resistance against external pressures, ensuring stability in diverse conditions.

Corrosion Resistance: The use of HDPE ensures corrosion resistance, making the pipes suitable for harsh environmental conditions and ensuring a long service life.

Flexibility and Durability: Despite the reinforced structure, these pipes maintain flexibility, allowing for easy installation in challenging terrains while ensuring long-term durability.

Smooth Inner Surface: The smooth inner surface reduces friction, promoting efficient fluid flow and minimizing the risk of debris accumulation within the pipes.

Chemical Resistance: HDPE’s innate resistance to chemicals makes these pipes versatile for various applications, including the transport of corrosive substances.

Applications of HDPE Wrapped Structural Wall Reinforced Pipes

Industrial Piping Systems: Ideal for industrial applications, offering a robust solution for transporting fluids in manufacturing and processing plants.

Water Transmission: Used in water transmission systems, ensuring a reliable and reinforced conduit for the efficient conveyance of water over long distances.

Mining and Dewatering: Applied in mining operations and dewatering projects, providing a reinforced structure for managing water levels in excavation areas.

Infrastructure Development: Used in infrastructure projects, including the construction of bridges and tunnels, where the pipes play a pivotal role in supporting structural integrity.

Wastewater Management: Suitable for wastewater conveyance, offering a durable and reinforced solution for the efficient transport of sewage.

Product Description

Specification parameters of Factory Direct Price HDPE Double Wall Plastic Corrugated underground Industrial Drainage Pipe

|

DN/ID

|

MIN.EVE.OD

|

MIN.EVE.OD

|

MIN.LAYER

WALL THICKNESS |

MIN.LAYER

WALL THICKNESS |

MIN. FLARING LENGTH

|

|

BN/ID200

|

230

|

195

|

2

|

0.8

|

60

|

|

BN/ID300

|

345

|

294

|

2.5

|

1.2

|

69

|

|

BN/ID400

|

465

|

392

|

3

|

1.6

|

77

|

|

BN/ID500

|

580

|

490

|

3.5

|

2

|

85

|

|

BN/ID600

|

700

|

588

|

4

|

3.5

|

96

|

|

BN/ID800

|

930

|

785

|

4.5

|

4.5

|

118

|

|

BN/ID1000

|

1160

|

985

|

6

|

5

|

140

|

|

BN/ID1200

|

1400

|

1185

|

8

|

5.5

|

162

|

|

BN/ID1500

|

1755

|

1485

|

10

|

6.5

|

178

|

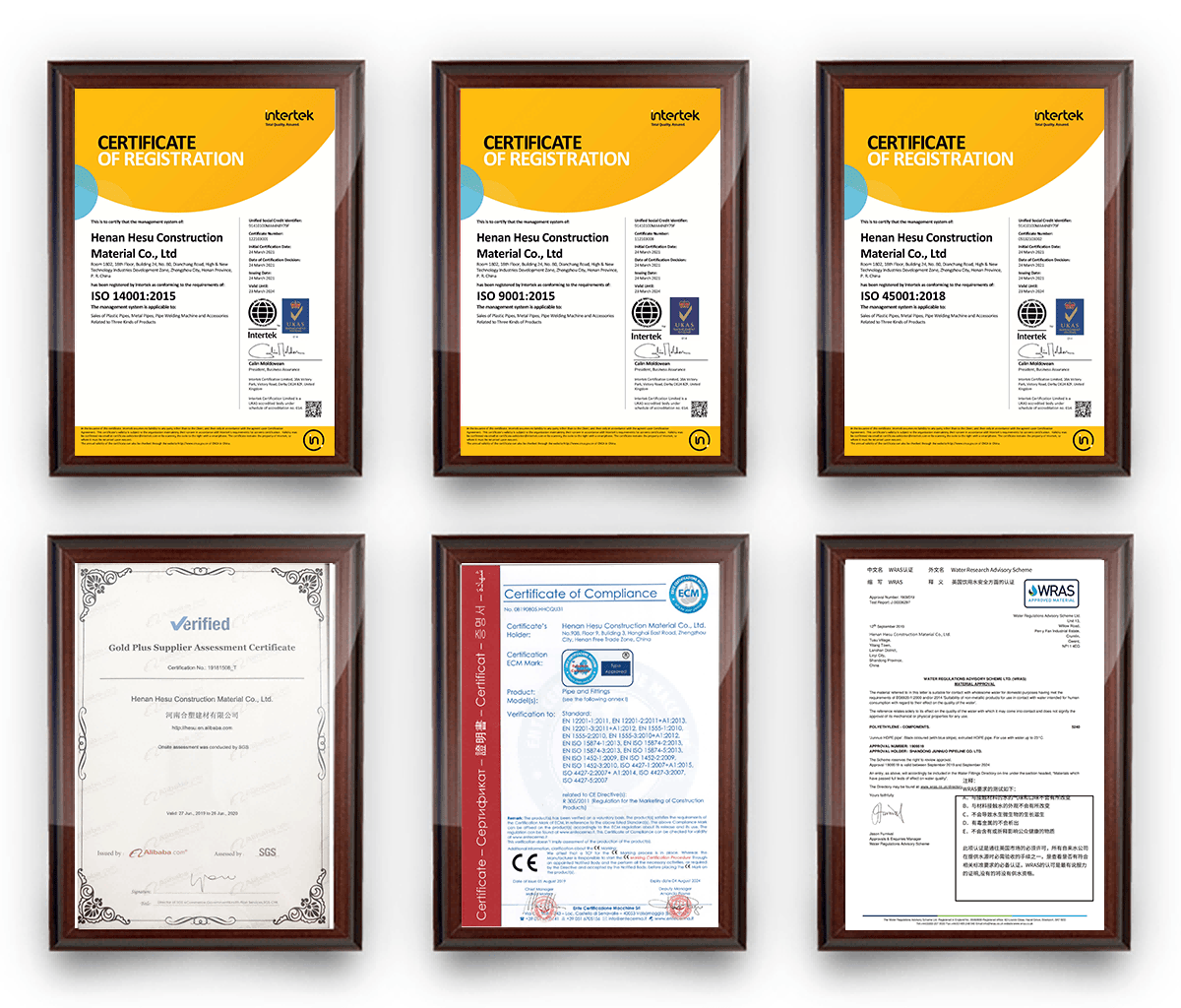

Zhongtong HDPE PIPE System Professional Supplier

Zhongtong HDPE PIPE System Professional Supplier