HDPE (High-Density Polyethylene) pipes are a critical component in modern water supply systems, known for their unique properties and applications. Here is an introduction to the performance and uses of HDPE pipes:

Performance of HDPE Pipes:

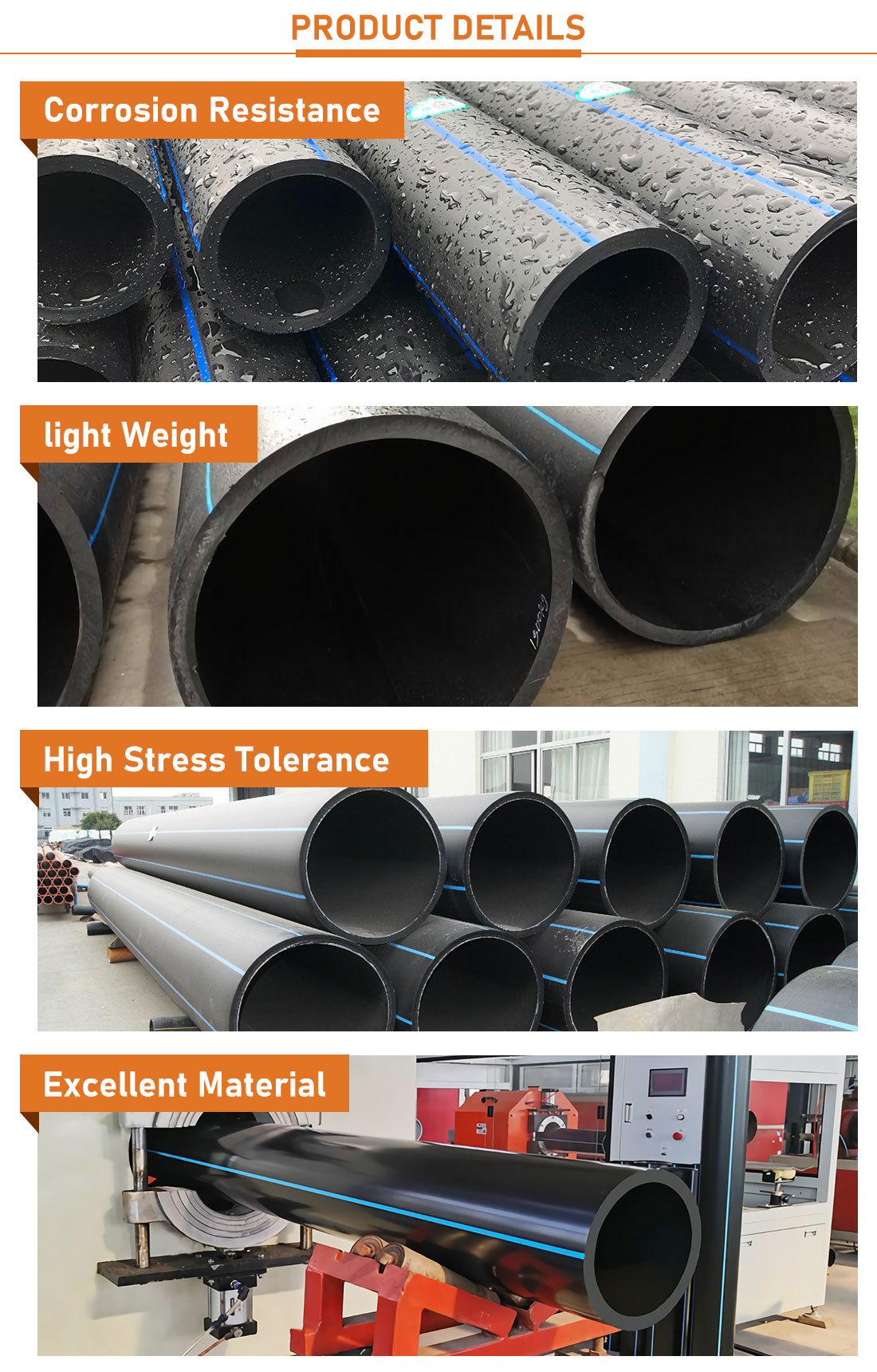

- Corrosion Resistance: HDPE pipes exhibit high resistance to a wide range of chemicals, including most acids, bases, and salts. This makes them particularly useful in chemically aggressive environments.

- Weather Resistance: The material can withstand harsh environmental conditions, such as strong sunlight and extreme temperatures, without degrading. This durability makes it ideal for outdoor applications.

- Flexibility and Toughness: HDPE pipes are flexible yet tough, enabling them to absorb impacts and resist damage during installation and use. This flexibility also allows for bending, reducing the need for fittings.

- Low Thermal Conductivity: These pipes have low thermal conductivity, minimizing heat loss in hot water applications and reducing the risk of freezing in cold environments.

- Longevity: HDPE pipes have a long service life, often exceeding 50 years, due to their resistance to wear and environmental factors.

Applications of HDPE Pipes:

- Potable Water Supply: Due to their safety and hygiene, HDPE pipes are widely used for transporting drinking water.

- Irrigation Systems: Their flexibility and durability make them ideal for various irrigation applications, including drip irrigation systems.

- Wastewater Management: HDPE pipes are used in sewage and wastewater systems because of their chemical and corrosion resistance.

- Industrial Applications: In industries where chemical resistance is crucial, such as chemical manufacturing, HDPE pipes are often used.

- Underground Piping: Their resistance to environmental stress and soil chemicals makes HDPE pipes suitable for underground water supply networks.

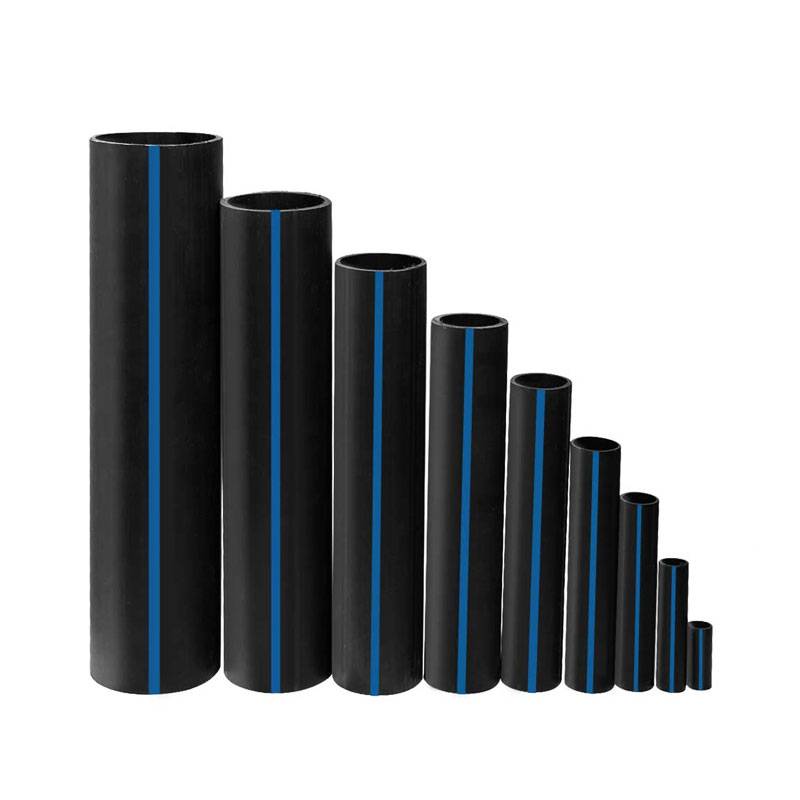

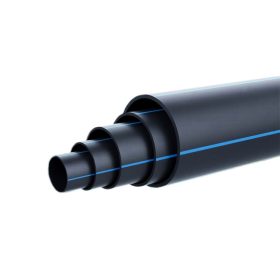

Product Description

|

Product Name

|

PE100 Water Supply HDPE Pipe

|

|

Color

|

Black with bule line

|

|

Standard

|

GB/T13663-2000,ISO 4427-1:2007

|

|

Specification

|

20-2000mm

|

|

Pressure

|

0.6MPa SDR26,0.8MPa SDR21,1MPa SDR17,1.25MPa SDR 13.6,1.6MPa SDR 11

|

|

Main application

|

Water Supplying and Draining

|

|

Guarantee

|

More than 50 years

|

Specification

|

Size

|

PN2.0MPa

|

PN1.6MPa

|

PN1.25MPa

|

PN1.0MPa

|

PN0.8MPa

|

PN0.6MPa

|

|

|

SDR 9

|

SDR 11

|

SDR 13.6

|

SDR 17

|

SDR 21

|

SDR 26

|

||

|

OD(inch)

|

OD(mm)

|

thickness

|

thickness

|

thickness

|

thickness

|

thickness

|

thickness

|

|

1/2

|

20

|

2.3

|

2.3

|

||||

|

3/4

|

25

|

3.0

|

2.3

|

2.3

|

|||

|

1

|

32

|

3.6

|

3.0

|

2.4

|

|||

|

1 1/4

|

40

|

4.5

|

3.7

|

3.0

|

2.4

|

||

|

1 1/2

|

50

|

5.6

|

4.6

|

3.7

|

3.0

|

||

|

2

|

63

|

7.1

|

5.8

|

4.7

|

3.8

|

||

|

2.5

|

75

|

8.4

|

6.8

|

5.6

|

4.5

|

||

|

3

|

90

|

10.1

|

8.2

|

6.7

|

5.4

|

4.3

|

|

|

4

|

110

|

12.3

|

10.0

|

8.1

|

6.6

|

5.3

|

4.2

|

|

5

|

125

|

14.0

|

11.4

|

9.2

|

7.4

|

6.0

|

4.8

|

|

140

|

15.7

|

12.7

|

10.3

|

8.3

|

6.7

|

5.4

|

|

|

6

|

160

|

17.9

|

14.6

|

11.8

|

9.5

|

7.7

|

6.2

|

|

7

|

180

|

20.1

|

16.4

|

13.3

|

10.7

|

8.6

|

6.9

|

|

8

|

200

|

22.4

|

18.2

|

14.7

|

11.9

|

9.6

|

7.7

|

|

225

|

25.2

|

20.5

|

16.6

|

13.4

|

10.8

|

8.6

|

|

|

10

|

250

|

27.9

|

22.7

|

18.4

|

14.8

|

11.9

|

9.6

|

|

11

|

280

|

31.3

|

25.4

|

20.6

|

16.6

|

13.4

|

10.7

|

|

12

|

315

|

35.2

|

28.6

|

23.2

|

18.7

|

15.0

|

12.1

|

|

14

|

355

|

39.7

|

32.2

|

26.1

|

21.1

|

16.9

|

13.6

|

|

16

|

400

|

44.7

|

36.3

|

29.4

|

23.7

|

19.1

|

15.3

|

|

18

|

450

|

50.3

|

40.9

|

33.1

|

26.7

|

21.5

|

17.2

|

|

20

|

500

|

55.8

|

45.4

|

36.8

|

29.7

|

23.9

|

19.1

|

|

22

|

560

|

62.5

|

50.8

|

41.2

|

33.2

|

26.7

|

21.4

|

|

24

|

630

|

70.3

|

57.2

|

46.3

|

37.4

|

30.0

|

24.1

|

|

28

|

710

|

79.3

|

64.5

|

52.2

|

42.1

|

33.9

|

27.2

|

|

32

|

800

|

89.3

|

72.6

|

58.8

|

47.4

|

38.1

|

30.6

|

|

36

|

900

|

81.8

|

66.2

|

53.3

|

42.9

|

34.4

|

|

|

40

|

1000

|

90.2

|

72.5

|

59.3

|

47.7

|

38.2

|

|

|

48

|

1200

|

88.2

|

67.9

|

57.2

|

45.9

|

||

|

55

|

1400

|

102.9

|

82.4

|

66.7

|

53.5

|

||

|

60

|

1500

|

110.2

|

88.2

|

71.4

|

57.6

|

||

|

65

|

1600

|

117.6

|

94.1

|

76.2

|

61.2

|

||

Zhongtong HDPE PIPE System Professional Supplier

Zhongtong HDPE PIPE System Professional Supplier