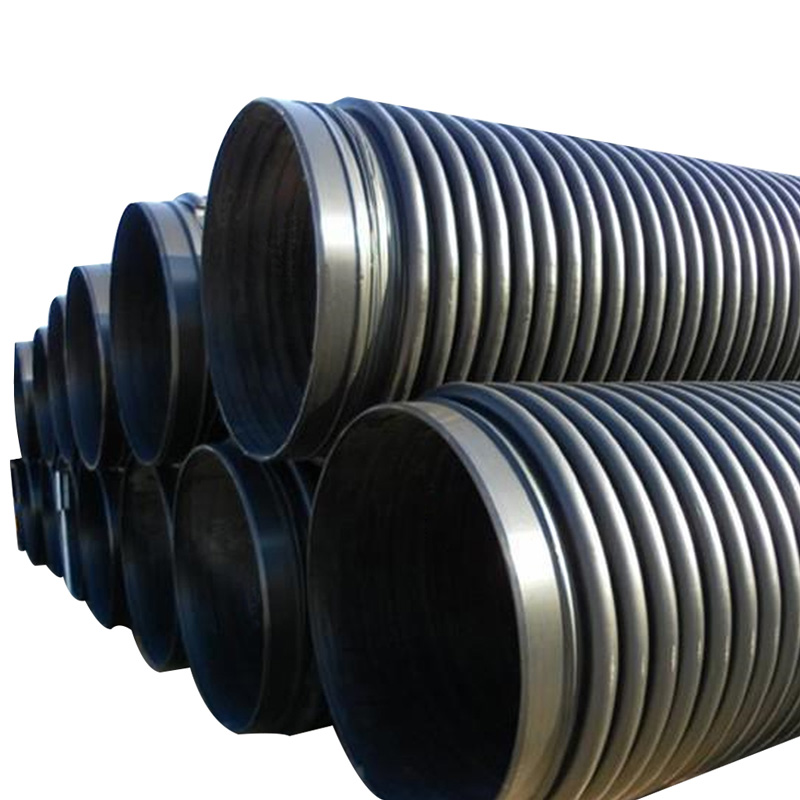

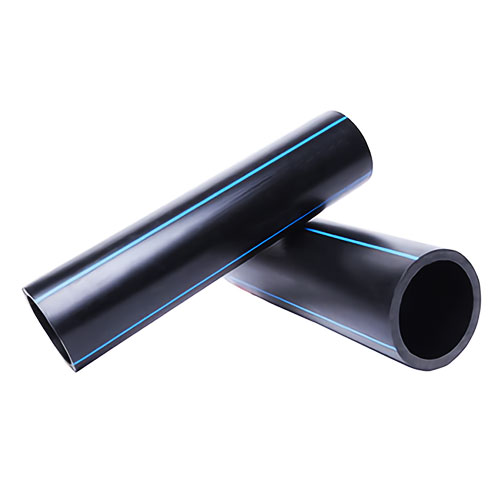

hdpe reinforced carat corrugated pipe stands at the forefront of modern fluid conveyance solutions, combining the strength of reinforced materials with the versatility of high-density polyethylene (HDPE).

Performance of HDPE Reinforced Krah Corrugation B-Pipe

- Reinforced Krah Corrugation: The incorporation of reinforced Krah corrugation enhances structural strength, providing exceptional resistance against external pressures, ensuring stability, and extending the lifespan of the pipes.

- Corrosion Resistance: HDPE material ensures corrosion resistance, making the pipes suitable for diverse environmental conditions and ensuring a long service life.

- Flexibility and Durability: Despite the reinforced structure, these pipes maintain flexibility, allowing for easy installation in challenging terrains while ensuring durability under various stress conditions.

- Smooth Inner Surface: The Krah corrugated design with a smooth inner surface minimizes friction, promoting efficient fluid flow, reducing pressure loss, and preventing debris accumulation within the pipes.

- Chemical Resistance: HDPE’s innate resistance to chemicals makes these pipes versatile for various applications, including the transport of corrosive substances.

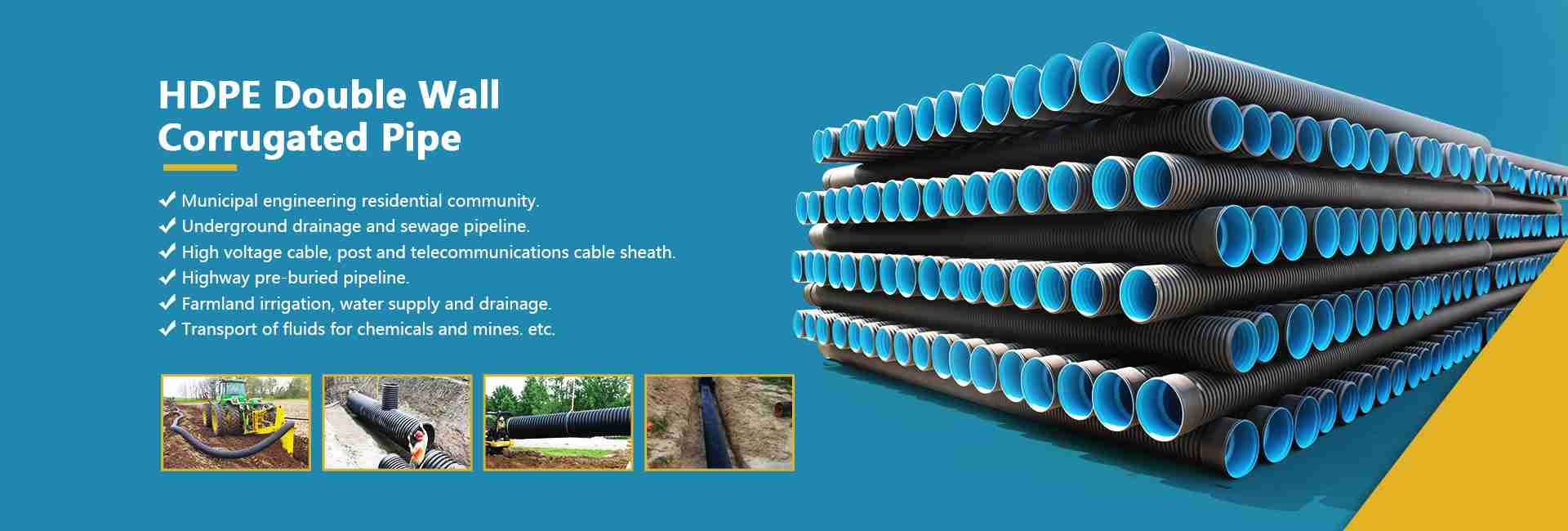

Applications of HDPE Reinforced Krah Corrugation B-Pipe

- Stormwater Drainage: Widely used in stormwater drainage systems, efficiently channeling rainwater away to prevent flooding.

- Sewer Systems: Applied in sewer systems for the conveyance of wastewater, providing a durable and reliable solution.

- Culvert Installations: Ideal for culverts and underpasses, facilitating the passage of water under roads, railways, or embankments.

- Mining and Dewatering: Applied in mining operations and dewatering projects, providing a reinforced structure for managing water levels in excavation areas.

- Infrastructure Development: Used in infrastructure projects for the construction of water supply networks, ensuring robust and lasting solutions.

Product Description

| Specifications | Ring stiffness | Tube wall thickness | Pitch | Rib tube diameter | Coating thickness |

| DN300 | SN8 | 4 | 120 | 27 | 3 |

| DN400 | SN8 | 4 | 120 | 34 | 3 |

| SN4 | 4 | 140 | 34 | 3 | |

| DN500 | SN8 | 4 | 100 | 42 | 3 |

| SN4 | 4 | 120 | 34 | 3 | |

| DN600 | SN8 | 5 | 100 | 42 | 4 |

| SN4 | 4 | 120 | 42 | 3 | |

| DN700 | SN8 | 5 | 140 | 54 | 4 |

| SN4 | 5 | 120 | 42 | 4 | |

| DN800 | SN8 | 5 | 140 | 65 | 4 |

| SN4 | 5 | 140 | 54 | 4 | |

| DN900 | SN8 | 6 | 140 | 65 | 5 |

| SN4 | 5 | 120 | 54 | 4 | |

| DN1000 | SN8 | 6 | 140 | 80 | 5 |

| SN4 | 5 | 140 | 65 | 4 | |

| DN1200 | SN8 | 9 | 120 | 80 | 6 |

| SN4 | 7 | 140 | 65 | 6 | |

| DN1400 | SN8 | 9 | 140 | 90 | 8 |

| SN4 | 6 | 140 | 80 | 5 | |

| DN1600 | SN8 | 12 | 180 | 110 | 6 |

| SN4 | 8 | 180 | 90 | 7 | |

| DN1800 | SN8 | 15 | 150 | 110 | 10 |

| SN4 | 9 | 180 | 110 | 7 | |

| DN2000 | SN8 | 11 | 120 | 65 | 10 |

| SN4 | 10 | 180 | 110 | 8 | |

| DN2500 | SN8 | 11 | 140 | 60 | 10 |

| SN4 | 9 | 100 | 65 | 8 |

Zhongtong HDPE PIPE System Professional Supplier

Zhongtong HDPE PIPE System Professional Supplier