HDPE Fish Cages represent an innovative solution in aquaculture, providing a controlled and sustainable environment for fish farming.

Performance of HDPE Fish Cages

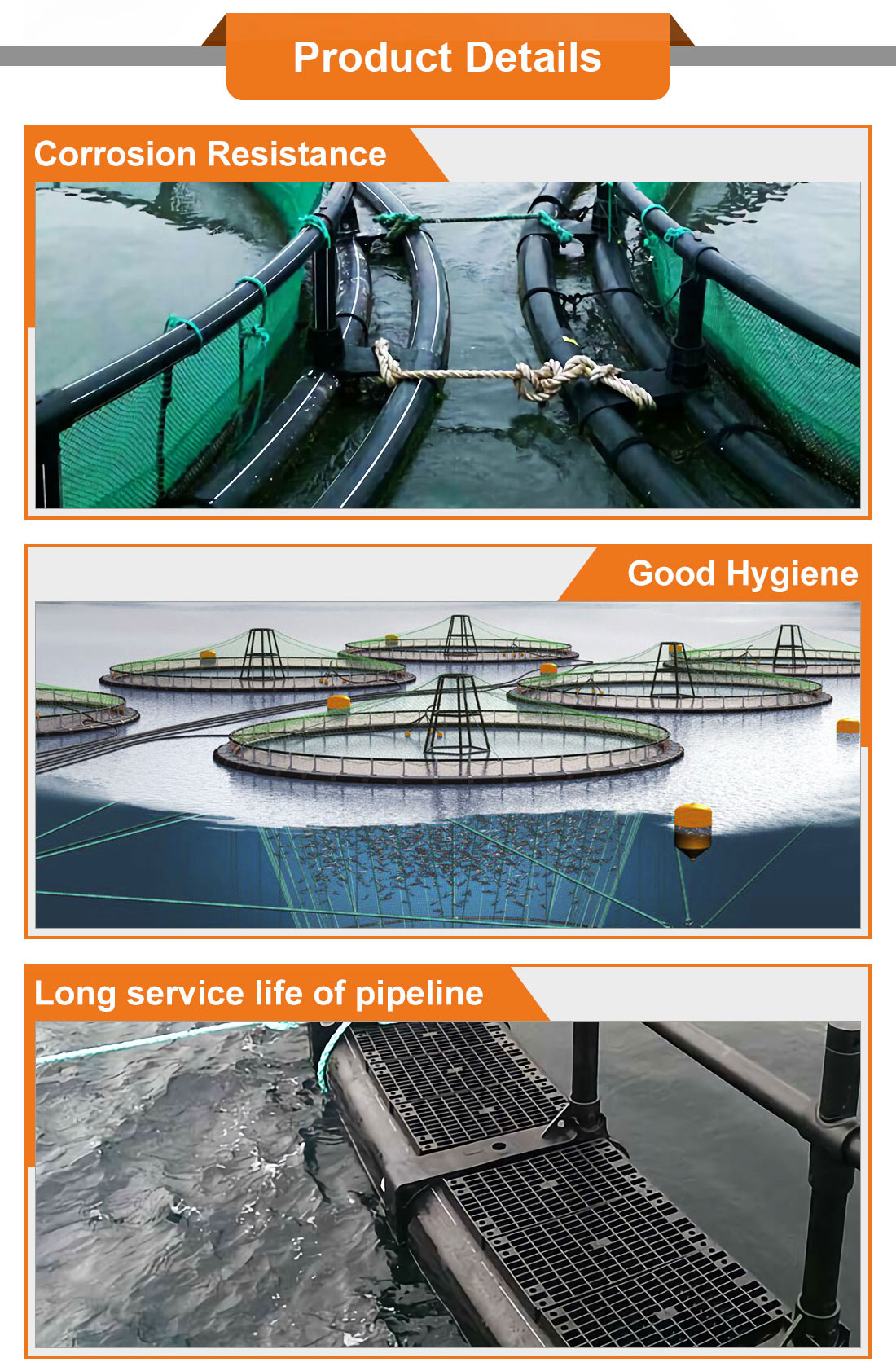

- High-Density Polyethylene (HDPE) Construction: The use of HDPE ensures durability, corrosion resistance, and longevity, withstanding the challenges of marine environments.

- Modular Design: HDPE Fish Cages often feature a modular structure, allowing for easy assembly, disassembly, and customization based on specific farming requirements.

- Buoyancy and Stability: The buoyant nature of HDPE contributes to the stability of the fish cages, ensuring they stay afloat and provide a secure environment for fish cultivation.

- Netting Systems: Equipped with specialized netting, HDPE Fish Cages provide optimal water circulation while preventing fish escape and protecting them from external predators.

- Environmental Compatibility: Designed with environmental considerations, these cages minimize the impact on the surrounding ecosystem, promoting sustainable and responsible aquaculture practices.

Applications of HDPE Fish Cages

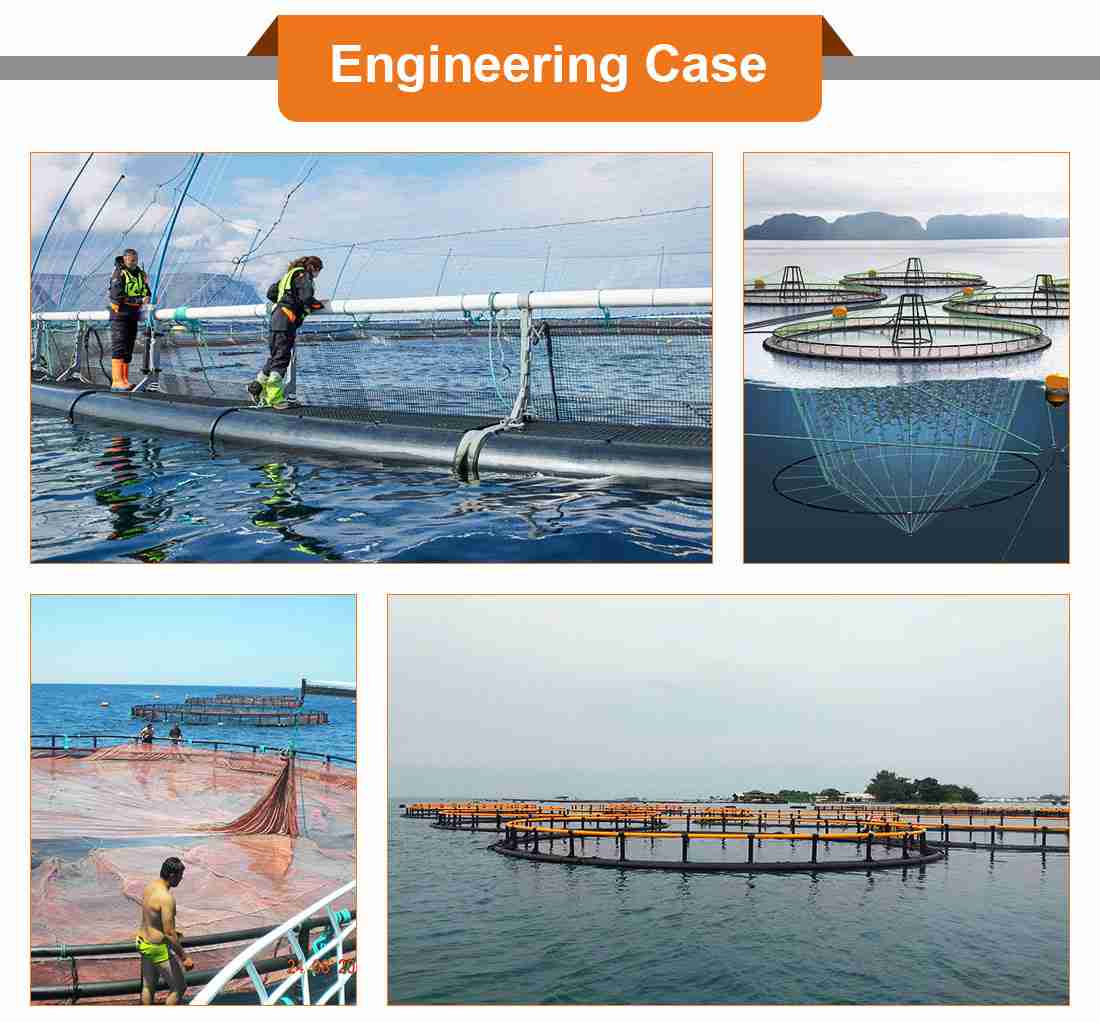

- Open Water Aquaculture: Deployed in open water bodies such as lakes, rivers, and coastal areas, HDPE Fish Cages offer controlled environments for fish farming, optimizing conditions for growth.

- Species Diversity: Suitable for cultivating a variety of fish species, including salmon, tilapia, and sea bass, enabling fish farmers to diversify their aquaculture operations.

- Research and Hatcheries: Used in research facilities and hatcheries to study fish behavior, growth patterns, and breeding, contributing to advancements in aquaculture science.

- Harbor and Coastal Farms: Deployed near harbors and coastal regions, these cages facilitate fish farming in proximity to processing and distribution centers, reducing transportation costs.

- Cage Farming Systems: Integrated into larger cage farming systems, HDPE Fish Cages play a key role in meeting the growing demand for sustainable and high-quality seafood.

Product Description

|

Circumference(M)

|

Diameter of floating pipe(MM)

|

Diameter of handrial pipe(MM)

|

Diameter of stand pipe(MM)

|

|

30

|

200mm

|

90mm

|

110mm

|

|

40

|

200mm/250mm

|

90mm/110mm

|

110mm/125mm

|

|

50

|

250mm

|

110mm

|

125mm

|

|

60

|

250mm/315mm

|

110mm

|

125mm

|

|

70

|

315mm

|

110mm/125mm

|

125mm

|

|

80

|

315mm

|

110mm/125mm

|

—

|

|

90

|

350mm

|

125mm

|

—

|

|

100

|

350mm/400mm

|

125mm

|

—

|

|

120

|

350mm/400mm

|

125mm

|

—

|

|

150

|

350mm/400mm

|

125mm

|

—

|

|

200

|

400mm

|

125mm

|

—

|

Zhongtong HDPE PIPE System Professional Supplier

Zhongtong HDPE PIPE System Professional Supplier