Ductile iron pipes, crafted from ductile iron material, are renowned for their core attributes: exceptional strength, remarkable corrosion resistance, and straightforward installation. The process involves adding a nodulizing agent during casting, transforming the iron’s graphite into spherical shapes, significantly enhancing the mechanical properties of the material.

Ductile Iron Pipe

The primary advantages of ductile iron pipes encompass:

Ductile Iron Pipe

High Strength: Ductile iron boasts significantly greater strength than gray cast iron, with a tensile strength exceeding 420 MPa, rendering it suitable for high-pressure applications.

Excellent Corrosion Resistance: Ductile iron pipes surpass steel counterparts in corrosion resistance, offering a service life of over 50 years and resistance to various corrosive environments.

Ease of Installation: Ductile iron pipes feature flexible joints, streamlining installation, reducing construction time, and resulting in cost savings.

Cost-Effectiveness: While the initial cost of ductile iron pipes may be higher than gray cast iron pipes, their extended service life and minimal maintenance requirements translate into superior long-term cost-effectiveness.

Ductile Iron Pipe

Ductile iron pipes find extensive application in urban water supply, drainage systems, natural gas transmission, and other sectors. In urban water supply, they withstand corrosion, ensuring the safety of water delivery. In drainage systems, their high strength and corrosion resistance ensure stable operation over extended periods. In the realm of natural gas transmission, ductile iron pipes’ robustness and excellent sealing properties guarantee the secure transportation of natural gas. With their outstanding performance and diverse applications, ductile iron pipes play an indispensable role in modern urban infrastructure and construction.

|

1

|

Standard:

|

ISO2531, EN545, EN598, etc

|

|

2

|

Size:

|

DN80~2600mm

|

|

3

|

Material:

|

Ductile Cast Iron GGG50

|

|

4

|

Pressure:

|

PN10, PN16, PN25,PN40

|

|

5

|

Class:

|

K9, K8, C25, C30, C40

|

|

6

|

Length:

|

6m, cut to 5.7m

|

|

7

|

Application:

|

Water supply project, drainage, sewage, irrigation, water pipeline.

|

|

8

|

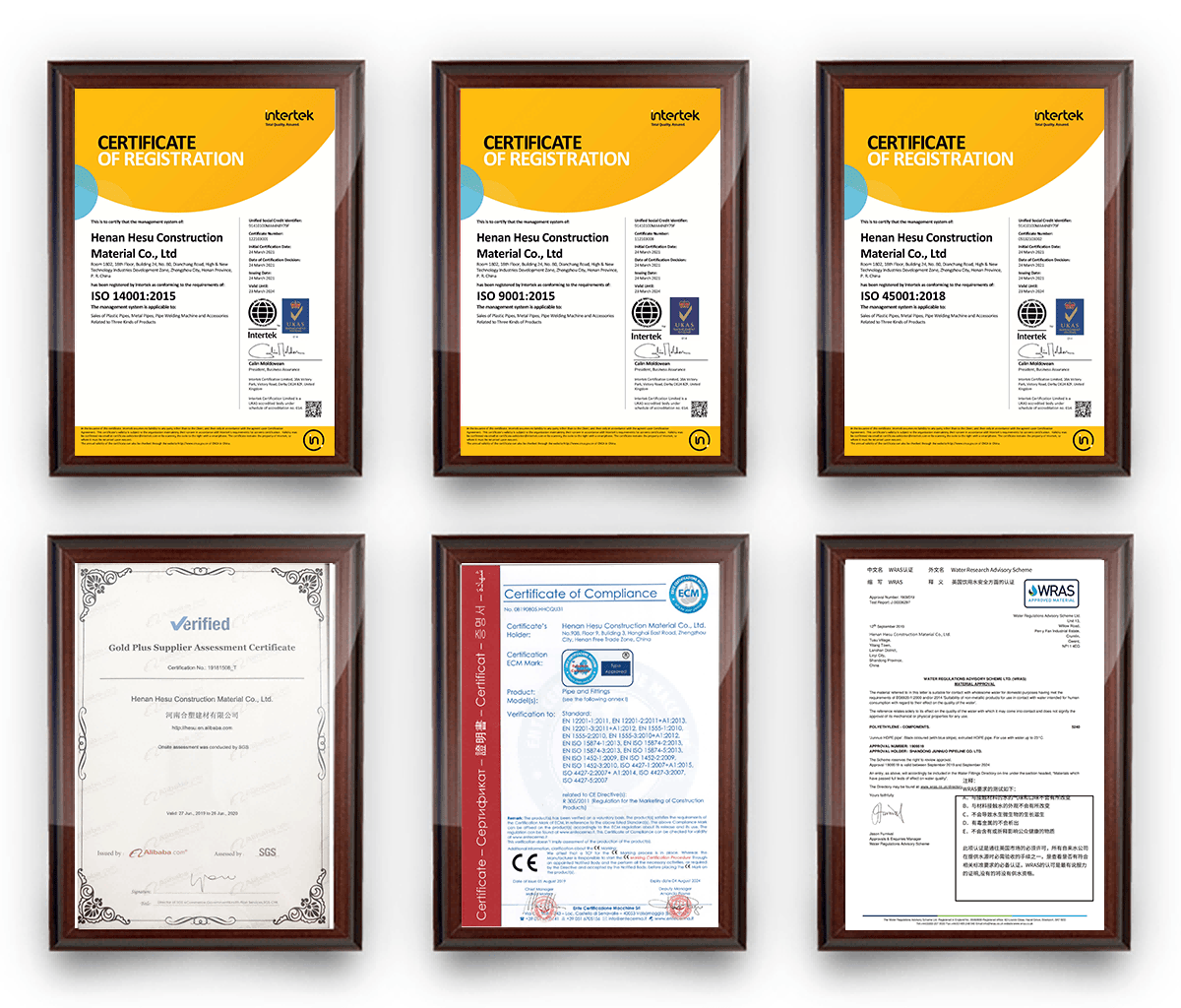

Certificate:

|

ISO9001, BV, WRAS, BSI

|

|

9 |

Internal Coating:

|

a). Portland cement mortar lining

|

|

b). Sulphate Resistant cement mortar lining

|

||

|

c). High-Aluminum cement mortar lining

|

||

|

d). Fusion bonded epoxy coating

|

||

|

e). Liquid epoxy painting

|

||

|

f). Black bitumen painting

|

||

|

10

|

External Coating:

|

a). zinc+bitumen(70microns) painting

|

|

b). Fusion bonded epoxy coating

|

||

|

c). Zinc-aluminum alloy+liquid epoxy painting

|

||

|

11

|

Packing:

|

Bundles, in bulk

|

Zhongtong HDPE PIPE System Professional Supplier

Zhongtong HDPE PIPE System Professional Supplier