Product Knowledge: Mastering the Art of Flanges

フランジ, essential components in industrial engineering, are connectors that facilitate the joining of pipes, valves, and other equipment. Understanding their types, such as slip-on, weld neck, and blind flanges, empowers professionals to choose the right fit for diverse applications. Dive into the realm of flange materials, from standard carbon steel to corrosion-resistant alloys, unlocking a world of possibilities for seamless integration.

Critical Considerations: Navigating the Flange Landscape

When dealing with flanges, precision is paramount. Ensure accurate measurements, especially concerning bolt patterns and flange faces, to guarantee a secure fit. Consider factors like temperature, 圧力, and the medium being transported – each plays a crucial role in selecting the ideal flange material and type. Prioritize quality in manufacturing, as flanges endure significant stress; investing in durable materials pays dividends in long-term reliability.

Installation Wisdom: Steps for Success

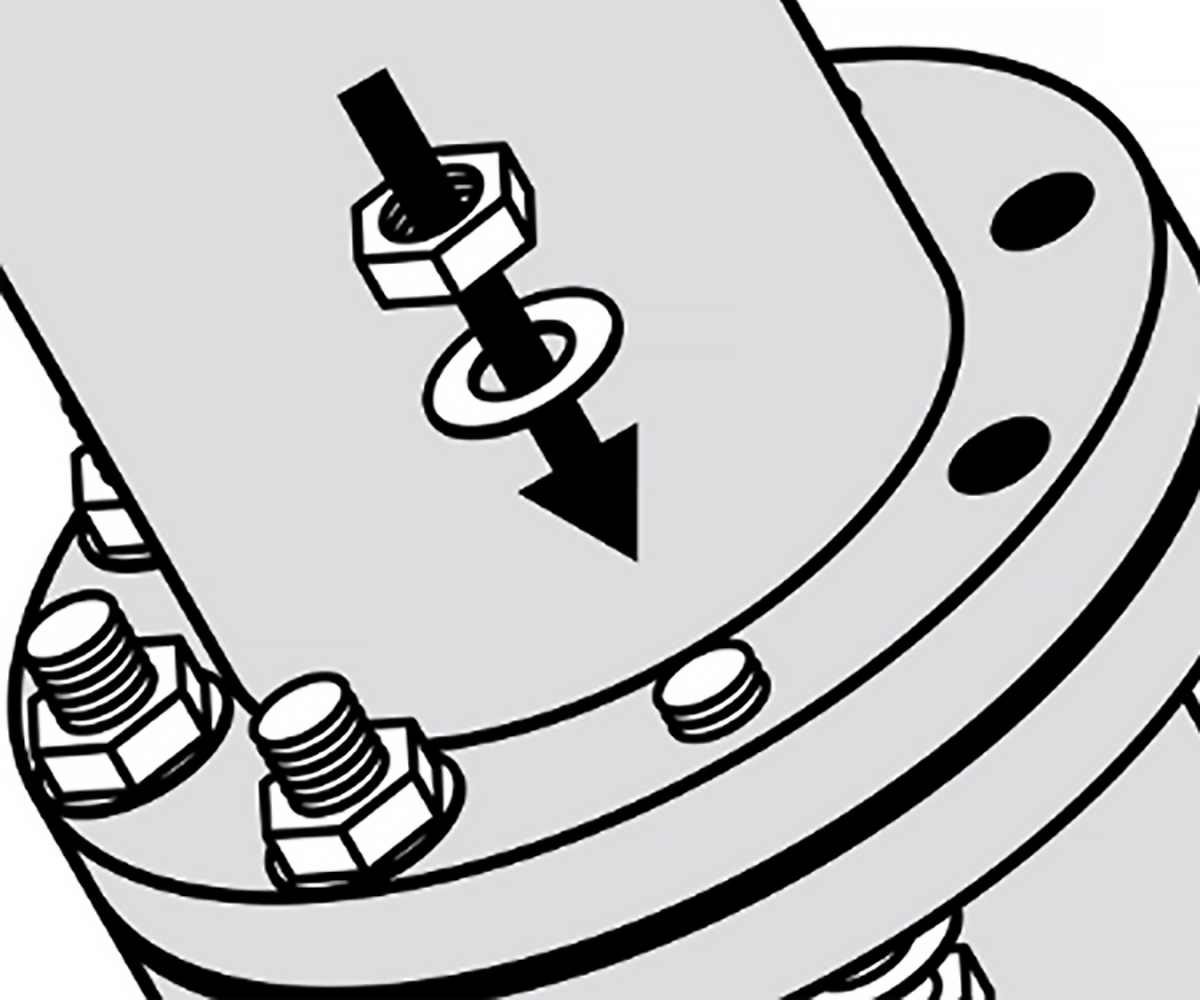

Flange installation demands meticulous attention to detail. Proper alignment, gasket placement, and bolt tightening are critical for leak-free connections. Utilize appropriate gaskets, taking into account the application’s demands and the flange type. Following industry standards and recommended torque values ensures a secure and efficient installation. Remember, the success of your system often hinges on the precision of flange installation.

Safety First: Handling Flanges with Care

When working with flanges, safety is non-negotiable. Always follow industry best practices, wear appropriate personal protective equipment, and adhere to safety guidelines during installation and maintenance. Regular inspections and monitoring for signs of wear, 腐食, or misalignment contribute to the overall safety and reliability of flange systems.

結論: フランジ, the Unsung Heroes of Connectivity

結論: フランジ, the Unsung Heroes of Connectivity

In the intricate world of industrial connectivity, flanges stand as unsung heroes. Armed with product knowledge and a keen understanding of critical considerations, professionals navigate the flange landscape with confidence. By prioritizing precise installation and emphasizing safety, flanges become not just connectors but guarantors of reliability and longevity in industrial systems. Master the art of flanges – where connectivity meets excellence.

Zhongtong HDPEパイプシステムプロフェッショナルサプライヤー

Zhongtong HDPEパイプシステムプロフェッショナルサプライヤー