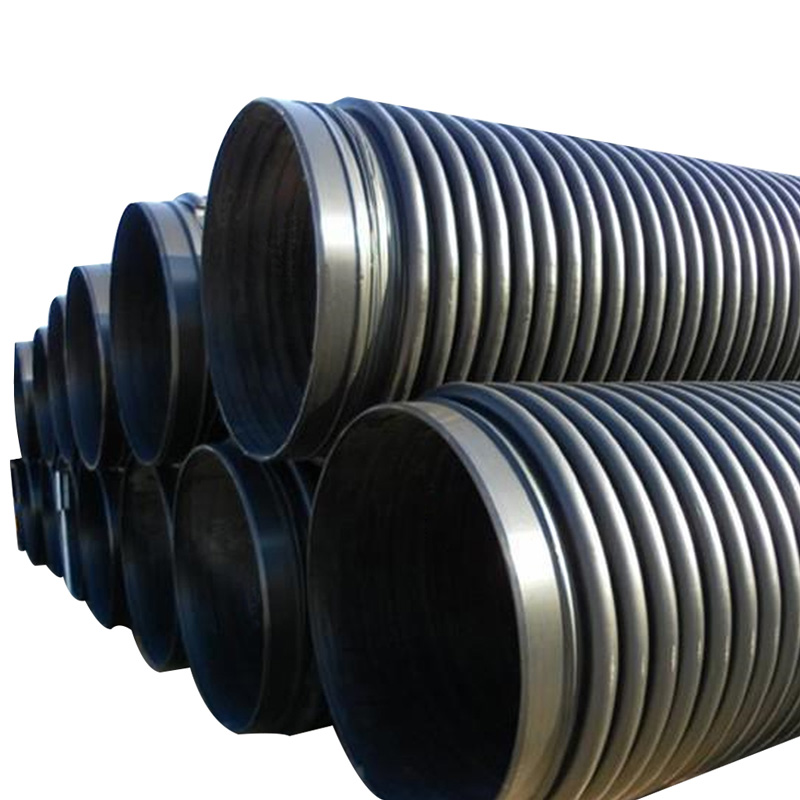

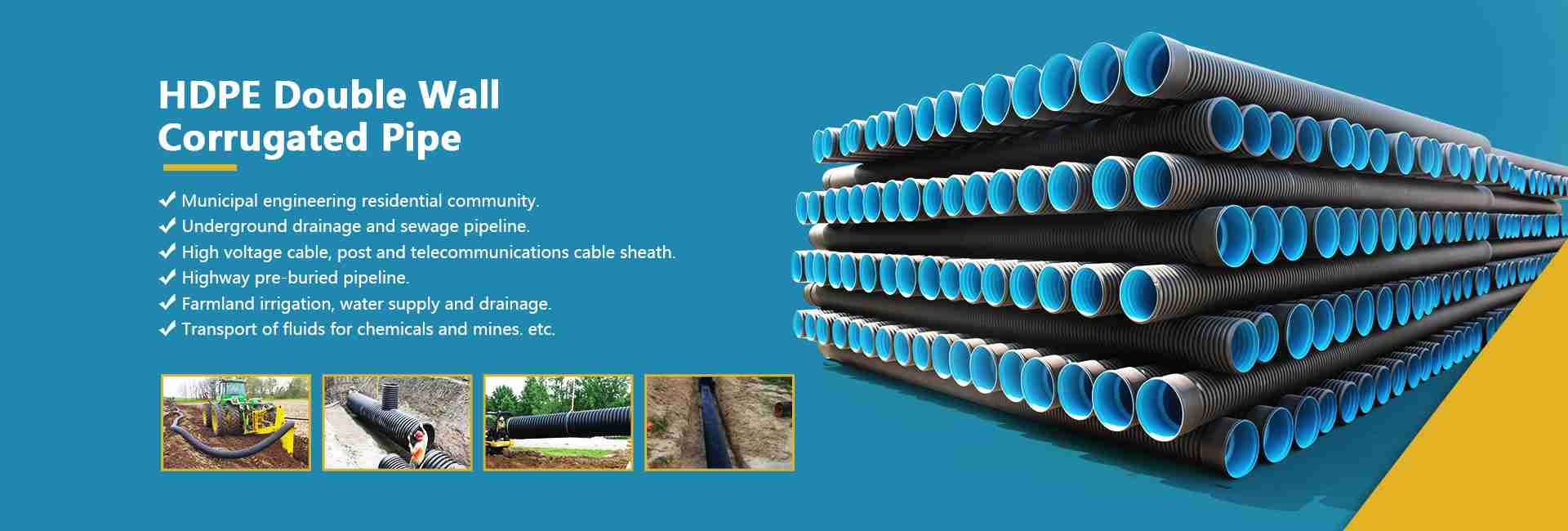

hdpe reinforced carat corrugated pipe stands at the forefront of modern fluid conveyance solutions, combining the strength of reinforced materials with the versatility of high-density polyethylene (HDPE).

Performance of HDPE Reinforced Krah Corrugation B-Pipe

- Reinforced Krah Corrugation: The incorporation of reinforced Krah corrugation enhances structural strength, providing exceptional resistance against external pressures, ensuring stability, and extending the lifespan of the pipes.

- Resistenza alla corrosione: Il materiale HDPE garantisce resistenza alla corrosione, rendendo i tubi adatti a diverse condizioni ambientali e garantendo una lunga durata.

- Flessibilità e durata: Despite the reinforced structure, these pipes maintain flexibility, allowing for easy installation in challenging terrains while ensuring durability under various stress conditions.

- Superficie interna liscia: The Krah corrugated design with a smooth inner surface minimizes friction, promoting efficient fluid flow, Riduzione della perdita di pressione, and preventing debris accumulation within the pipes.

- Resistenza chimica: HDPE’s innate resistance to chemicals makes these pipes versatile for various applications, compreso il trasporto di sostanze corrosive.

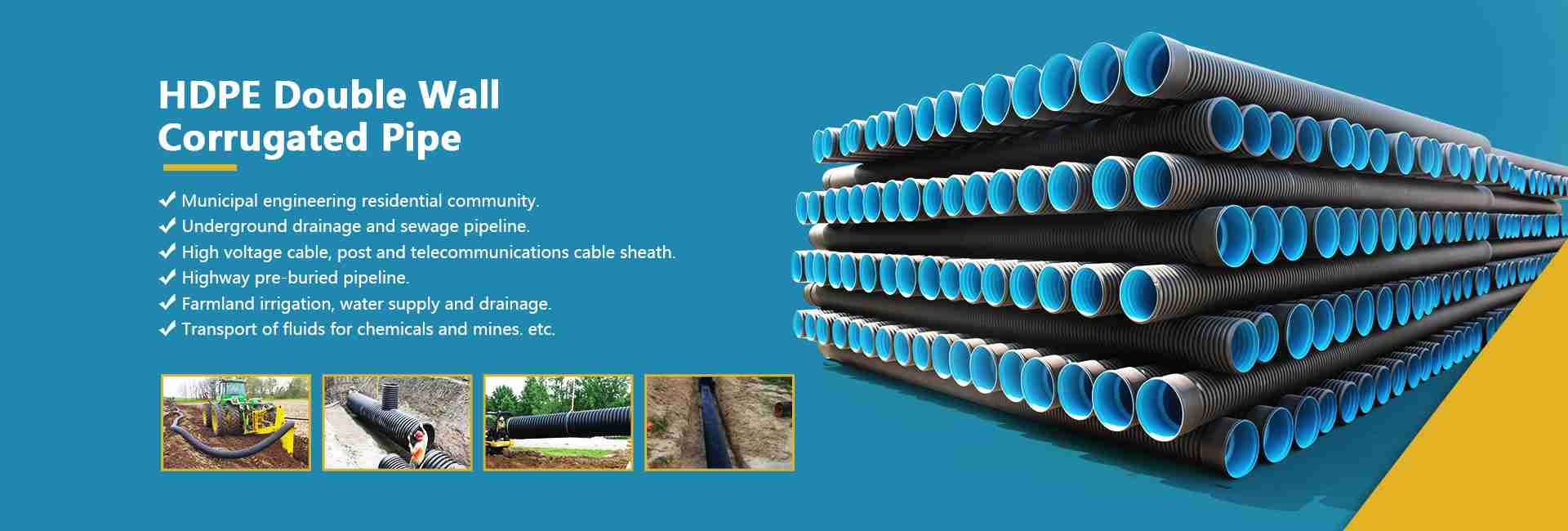

Applications of HDPE Reinforced Krah Corrugation B-Pipe

- Stormwater Drainage: Ampiamente usato nei sistemi di drenaggio delle acque piovane, incanalare in modo efficiente l'acqua piovana per evitare allagamenti.

- Sistemi fognari: Applicato in sistemi fognari per il convogliamento di acque reflue, Fornire una soluzione durevole e affidabile.

- Installazioni di canali sotterranei: Ideale per canali sotterranei e sottopassi, facilitare il passaggio dell'acqua sotto le strade, ferrovie, o argini.

- Mining and Dewatering: Applied in mining operations and dewatering projects, providing a reinforced structure for managing water levels in excavation areas.

- Sviluppo dell'infrastruttura: Used in infrastructure projects for the construction of water supply networks, ensuring robust and lasting solutions.

Descrizione del prodotto

| Indicazioni |

Rigidità dell'anello |

Tube wall thickness |

Pitch |

Rib tube diameter |

Coating thickness |

| DN300 |

SN8 |

4 |

120 |

27 |

3 |

| DN400 |

SN8 |

4 |

120 |

34 |

3 |

| SN4 |

4 |

140 |

34 |

3 |

| DN500 |

SN8 |

4 |

100 |

42 |

3 |

| SN4 |

4 |

120 |

34 |

3 |

| DN600 |

SN8 |

5 |

100 |

42 |

4 |

| SN4 |

4 |

120 |

42 |

3 |

| DN700 |

SN8 |

5 |

140 |

54 |

4 |

| SN4 |

5 |

120 |

42 |

4 |

| DN800 |

SN8 |

5 |

140 |

65 |

4 |

| SN4 |

5 |

140 |

54 |

4 |

| DN900 |

SN8 |

6 |

140 |

65 |

5 |

| SN4 |

5 |

120 |

54 |

4 |

| DN1000 |

SN8 |

6 |

140 |

80 |

5 |

| SN4 |

5 |

140 |

65 |

4 |

| DN1200 |

SN8 |

9 |

120 |

80 |

6 |

| SN4 |

7 |

140 |

65 |

6 |

| DN1400 |

SN8 |

9 |

140 |

90 |

8 |

| SN4 |

6 |

140 |

80 |

5 |

| DN1600 |

SN8 |

12 |

180 |

110 |

6 |

| SN4 |

8 |

180 |

90 |

7 |

| DN1800 |

SN8 |

15 |

150 |

110 |

10 |

| SN4 |

9 |

180 |

110 |

7 |

| DN2000 |

SN8 |

11 |

120 |

65 |

10 |

| SN4 |

10 |

180 |

110 |

8 |

| DN2500 |

SN8 |

11 |

140 |

60 |

10 |

| SN4 |

9 |

100 |

65 |

8 |

Particolari dell'imballaggio: I nostri tubi in HDPE sono imballati in modo sicuro in contenitori o secondo le esigenze del cliente, assicurandoti che ti raggiungano in perfette condizioni. Utilizziamo materiali robusti per l'imballaggio per proteggere i tubi durante il trasporto, Adatto a varie dimensioni e quantità.

Dettagli di consegna: Garantiamo un processo di consegna rapido, con gli ordini che vengono spediti entro 15 giorni dopo la conferma del pagamento. La nostra efficiente rete logistica garantisce che il tuo ordine arrivi in modo rapido e sicuro, indipendentemente dalla tua posizione. Ci sforziamo di rispettare scadenze ravvicinate mantenendo i più alti standard di servizio e qualità del prodotto.

Di seguito è riportata la nostra immagine dettagliata

Zhongtong ha ottenuto varie certificazioni, compresa la certificazione nazionale per le imprese high-tech, Certificazione del servizio post-vendita a cinque stelle, Certificazione del Sistema di Gestione per la Qualità, e certificazione del sistema di gestione ambientale.

L'azienda vanta una clientela diversificata, dopo aver servito oltre 2,680 grandi imprese, tra cui prestigiose istituzioni come l'Università della Scienza e della Tecnologia di Nanchino, Università di Zhejiang, enti governativi come l'Ufficio per gli affari idrici di Taicang, strutture di spicco come la stazione ferroviaria ad alta velocità di Changzhou, e aziende ben note come Nongfu Spring, Gruppo Giardino di campagna, e la linea della metropolitana di Nanchino 4.

Q: Qual è il tuo MOQ?

Un: Come richiesta del cliente.

Q: Perchè sceglierci?

Un: Siamo un professionista e leader della fabbrica di tubi in HDPE, Offriamo servizi one-stop del sistema di tubazioni con il prezzo competitivo ed i tempi di consegna veloci, e ci assicuriamo che la nostra qualità non sia seconda a nessuno.

Q: Come acquistare il prodotto?

Un: Contattaci via e-mail o tramite Trade Manager, e ci informa di quale prodotto e quantità hai bisogno, ti contatteremo

si immediatamente. Più specifica le informazioni che hai fornito, più velocemente e più facilmente otterrai il preventivo.

Q: Posso fare il mio design e logo sul prodotto?

Un: Sì, facciamo OEM. Benvenuto partner da tutto il mondo, possiamo fare il vostro prodotto in Cina.

Q: qual è il termine di pagamento?

Un: Importo dell'ordine <=1.000 USD, 100% In anticipo. Importo dell'ordine>=1.000 USD, 30% T/T in anticipo, equilibrio prima della spedizione.

Importo dell'ordine>20,000USD, 30% T/T in anticipo, bilanciamento L/C a vista accettabile.

Importo dell'ordine>100,000USD, 100% L/C a vista accettabile.

Q: Ho ancora altre domande?

Un: Utilizzate la tabella sottostante e inviateci le vostre domande. Grazie.

Zhongtong HDPE TUBO Sistema Fornitore Professionale

Zhongtong HDPE TUBO Sistema Fornitore Professionale