Introduction

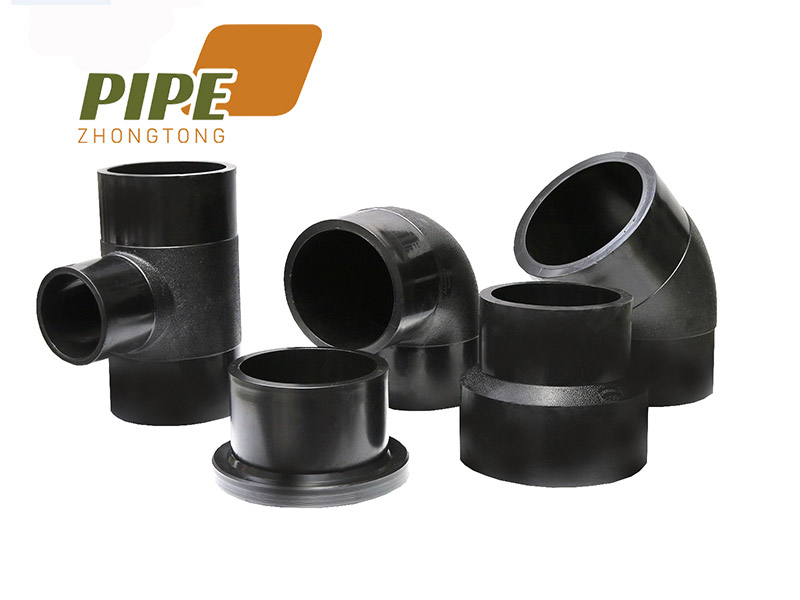

HDPE butt fusion fitting are widely used in municipal engineering projects like water supply and wastewater management. Questi raccordi creano forti, long-lasting pipe connections that are easy to install and maintain. Here’s why HDPE butt fusion fittings are so useful for municipal projects.

1. Why Use HDPE Butt Fusion Fittings?

In municipal projects, pipes must be strong and leak-proof. HDPE butt fusion fittings create a solid, reliable connection that can handle pressure, temperature changes, and ground movement without breaking or leaking.

2. Key Benefits for Municipal Projects

- Long-Lasting: HDPE fittings can last over 50 anni, saving money on repairs and replacements.

- Leak-Proof: The fusion process creates a seamless connection that doesn’t leak.

- Flexible and Strong: HDPE is flexible, so it can handle ground shifts without cracking.

- Corrosion-Resistant: HDPE doesn’t rust, keeping water clean and safe for longer.

3. Ecologico

HDPE is fully recyclable and requires less energy to produce and install. This helps reduce the environmental impact of construction projects.

4. Installation Process

To install HDPE butt fusion fittings, a machine heats the ends of the pipe and fitting, and they are pressed together until they cool and bond. This creates a secure, leak-proof joint.

5. Common Municipal Uses

- Water Supply Lines

- Sistemi fognari e fognari

- Stormwater Drainage

- Distribuzione Gas

Conclusione

HDPE butt fusion fittings provide a durable and eco-friendly solution for municipal piping projects. They help create safe, leak-proof systems that need little maintenance and can last for decades.

Zhongtong HDPE TUBO Sistema Fornitore Professionale

Zhongtong HDPE TUBO Sistema Fornitore Professionale