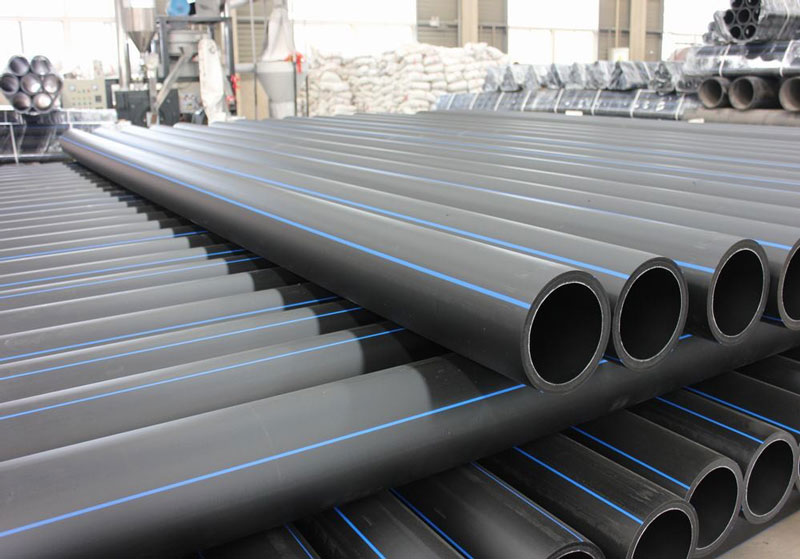

HDPE pipes have become an indispensable part of modern engineering construction due to their unique physical and chemical properties. Not only do they exhibit excellent corrosion resistance and durability, but they also perform remarkably well in terms of environmental protection and energy conservation, thus finding wide applications across various sectors. This article will delve into several major products of HDPE pipes and their respective application areas.

1. HDPE Water Supply Pipe

HDPE water supply pipes, renowned for their excellent corrosion resistance and flexibility, are extensively used in urban water supply, rural drinking water projects, and industrial water circulation systems. These pipes can withstand the corrosion of various chemical media and boast easy installation and low maintenance costs.

2. HDPE Gas Pipe

HDPE gas pipes are the ideal choice for transporting natural gas and liquefied petroleum gas. They possess outstanding tensile strength and pressure resistance, ensuring the safe and stable supply of gas. Additionally, the flexibility of HDPE gas pipes enables them to adapt to different terrains, reducing construction difficulties.

3. HDPE Silicon-core Pipe

Silicon-core pipes, a special type of HDPE pipe with a layer of silicone core, are primarily used for laying telecommunication and power lines. These pipes offer excellent insulation performance and tensile strength, protecting the lines from external environmental influences.

4. HDPE Steel Framed Pipe

Combining the corrosion resistance of HDPE with the high strength of steel, steel-framed pipes find wide applications in marine engineering, bridge construction, road laying, and other fields. These pipes can withstand heavy loads and harsh environments.

5. HDPE Butt Fusion Fittings

Butt fusion fittings are crucial components for connecting HDPE pipes. Through butt fusion technology, seamless connections of pipes are achieved, ensuring the sealing and durability of the pipeline system.

6. HDPE Electro-Fusion Fittings

Electro-fusion fittings utilize electrical heating principles to fuse the pipe ends with fittings into a solid connection. This connection method is suitable for the rapid installation of large-diameter pipes.

7. HDPE Segmented Pipe Fittings

Segmented pipe fittings are detachable pipe connection methods, facilitating the maintenance and replacement of pipes. These fittings are commonly used in situations requiring frequent maintenance.

8. HDPE Micro Duct Tube

Micro duct tubes are mainly used for laying optical fibers and cables. Their small diameter and lightweight characteristics make the laying work more convenient.

9. HDPE Porous Pipe For Optical Cable

This porous pipe is specifically designed for protecting optical cables. Its porous structure allows the optical cables to pass through while providing necessary support and protection.

10. Drip Irrigation Pipe

Drip irrigation pipes are key components in agricultural irrigation systems. They can precisely deliver water and nutrients directly to the roots of plants, enhancing the efficiency of water resources utilization.

11. HDPE Dredging Pipe

Dredging pipes are used for underwater dredging operations. Their corrosion resistance and abrasion resistance enable them to work in harsh marine environments for extended periods.

12. HDPE Tube Floating Dock

Tube floating docks utilize the buoyancy of HDPE pipes to construct temporary or permanent water structures, such as docks and floating bridges.

The diversity and wide application areas of HDPE pipes make them essential materials in modern engineering construction. With continuous technological advancements and market expansions, HDPE pipes are expected to play an even greater role in the future of construction and engineering. For more information about HDPE pipes, please visit our BLOG and read relevant product introductions.

Zhongtong HDPE PIPE System Professional Supplier

Zhongtong HDPE PIPE System Professional Supplier