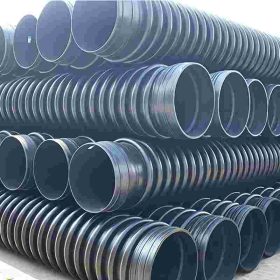

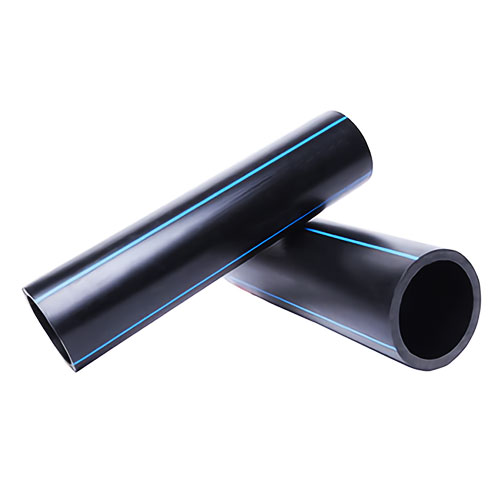

HDPE Wrapped Structural Wall Reinforced Pipes represent a cutting-edge solution for various infrastructure needs, combining the strength of reinforced materials with the durability of high-density polyethylene (HDPE).

Performance of HDPE Wrapped Structural Wall Reinforced Pipes

Structural Reinforcement: The pipes feature a reinforced structural wall, enhancing strength and providing resistance against external pressures, ensuring stability in diverse conditions.

Korrosionsbeständigkeit: The use of HDPE ensures corrosion resistance, making the pipes suitable for harsh environmental conditions and ensuring a long service life.

Flexibilität und Langlebigkeit: Trotz der verstärkten Struktur, Diese Rohre behalten die Flexibilität bei, allowing for easy installation in challenging terrains while ensuring long-term durability.

Glatte Innenfläche: Die glatte Innenfläche reduziert die Reibung, promoting efficient fluid flow and minimizing the risk of debris accumulation within the pipes.

Chemische Beständigkeit: Die inhärente Beständigkeit von HDPE gegen Chemikalien macht diese Rohre vielseitig einsetzbar für verschiedene Anwendungen, einschließlich des Transports von ätzenden Stoffen.

Applications of HDPE Wrapped Structural Wall Reinforced Pipes

Industrielle Rohrleitungssysteme: Ideal for industrial applications, offering a robust solution for transporting fluids in manufacturing and processing plants.

Water Transmission: Used in water transmission systems, ensuring a reliable and reinforced conduit for the efficient conveyance of water over long distances.

Bergbau und Entwässerung: Anwendung im Bergbau und bei Entwässerungsprojekten, Bereitstellung einer verstärkten Struktur zur Steuerung des Wasserspiegels in Aushubbereichen.

Entwicklung der Infrastruktur: Used in infrastructure projects, including the construction of bridges and tunnels, where the pipes play a pivotal role in supporting structural integrity.

Abwassermanagement: Suitable for wastewater conveyance, offering a durable and reinforced solution for the efficient transport of sewage.

Produktbeschreibung

Specification parameters of Factory Direct Price HDPE Double Wall Plastic Corrugated underground Industrial Drainage Pipe

|

DN/ID

|

MIN.EVE.OD

|

MIN.EVE.OD

|

MIN.LAYER

WALL THICKNESS |

MIN.LAYER

WALL THICKNESS |

MIN. FLARING LENGTH

|

|

BN/ID200

|

230

|

195

|

2

|

0.8

|

60

|

|

BN/ID300

|

345

|

294

|

2.5

|

1.2

|

69

|

|

BN/ID400

|

465

|

392

|

3

|

1.6

|

77

|

|

BN/ID500

|

580

|

490

|

3.5

|

2

|

85

|

|

BN/ID600

|

700

|

588

|

4

|

3.5

|

96

|

|

BN/ID800

|

930

|

785

|

4.5

|

4.5

|

118

|

|

BN/ID1000

|

1160

|

985

|

6

|

5

|

140

|

|

BN/ID1200

|

1400

|

1185

|

8

|

5.5

|

162

|

|

BN/ID1500

|

1755

|

1485

|

10

|

6.5

|

178

|

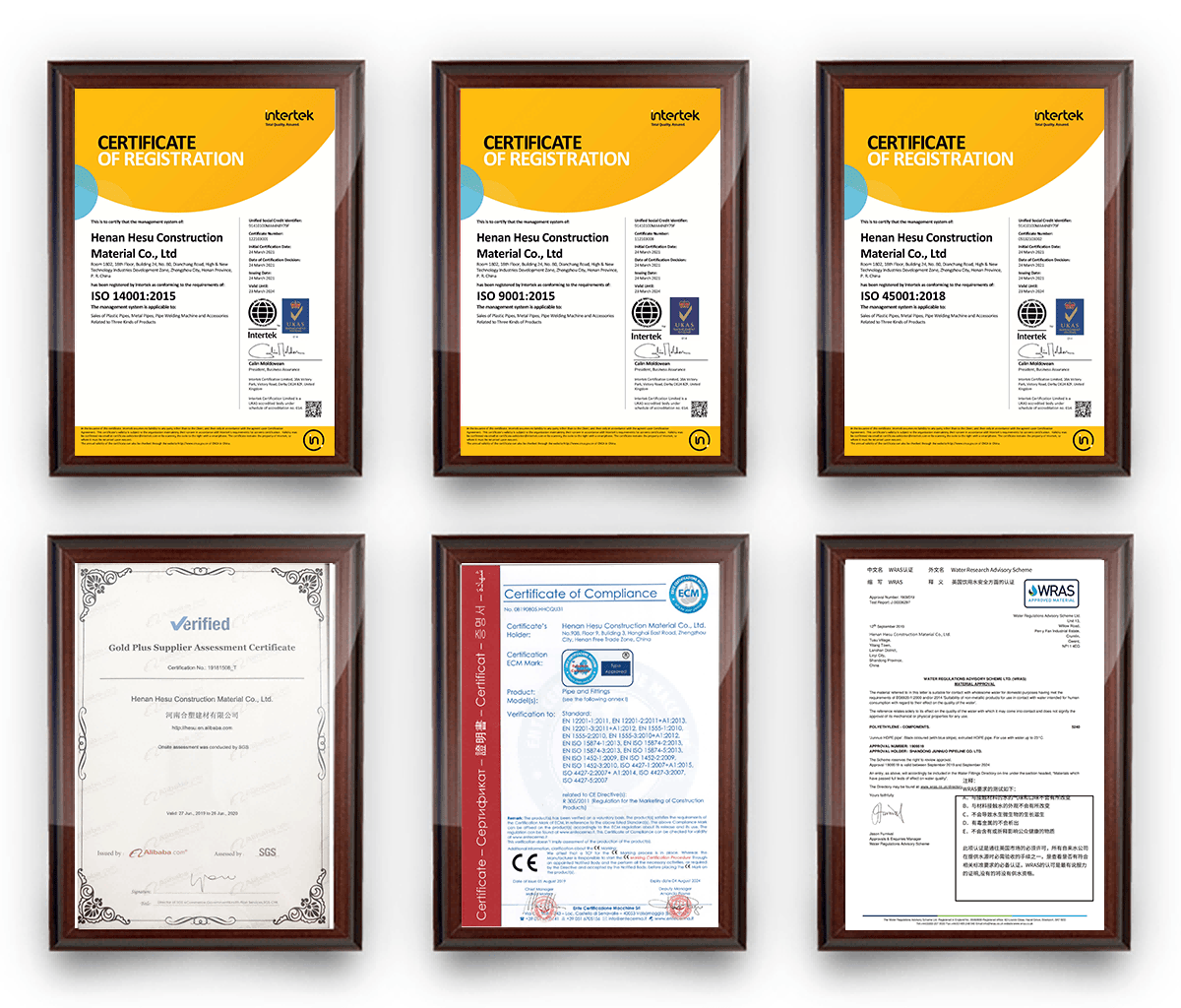

Zhongtong HDPE PIPE System Professioneller Lieferant

Zhongtong HDPE PIPE System Professioneller Lieferant