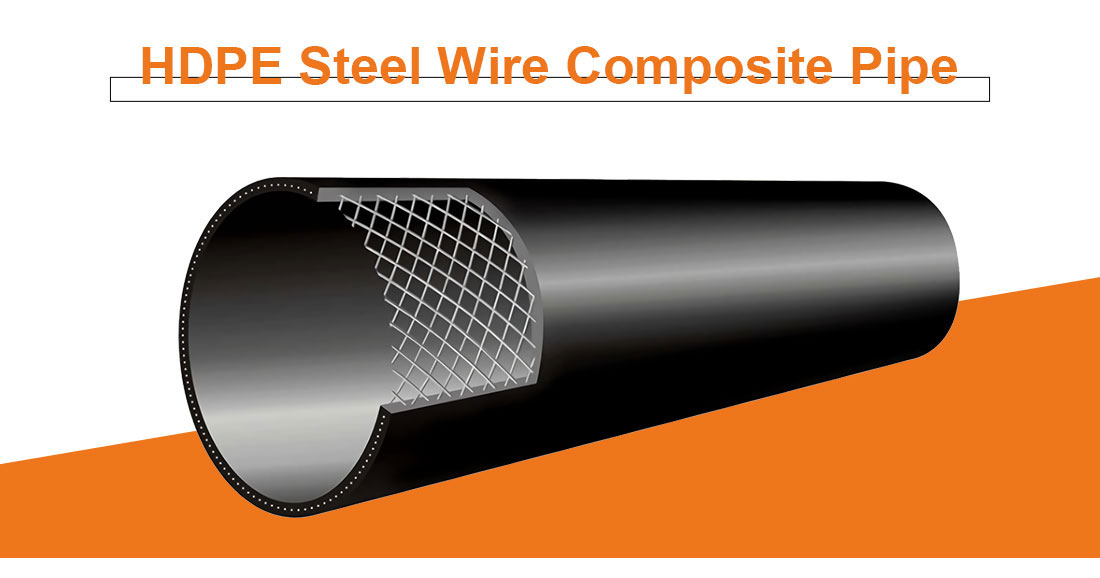

HDPE-Stahlrahmenrohre stellen einen bedeutenden Fortschritt in der Rohrleitungstechnik dar, Kombination der Festigkeit von Stahl mit der Flexibilität und Korrosionsbeständigkeit von Polyethylen hoher Dichte (HDPE). Diese Hybridstruktur bietet eine robuste Lösung für verschiedene Anwendungen.

Leistung von Rohren mit HDPE-Stahlrahmen

- Verbesserte strukturelle Festigkeit: Der Stahlrahmen in diesen Rohren bietet eine überlegene mechanische Festigkeit und Steifigkeit, Dadurch können sie im Vergleich zu Standard-HDPE-Rohren höheren Innen- und Außendrücken standhalten.

- Korrosionsbeständigkeit: Die äußere HDPE-Schicht bietet eine hervorragende Beständigkeit gegen Korrosion und chemische Angriffe, Schutz des Stahlrahmens und Gewährleistung einer längeren Lebensdauer des Rohrs.

- Flexibilität und Rissbeständigkeit: Trotz der Stahlbewehrung, Diese Rohre behalten ein gewisses Maß an Flexibilität bei, was für HDPE charakteristisch ist. Diese Flexibilität trägt zur Beständigkeit gegen Spannungsrisse in der Umgebung bei.

- Abriebfestigkeit: Die innere HDPE-Schicht sorgt für eine glatte Oberfläche, die den Verschleiß durch abrasive Materialien minimiert, Damit eignen sie sich ideal für den Transport von Feststoffen.

- Temperatur- und Schlagfestigkeit: Diese Rohre können in einem Temperaturbereich effektiv betrieben werden und sind auch widerstandsfähig gegen Stöße, was für raue Umgebungsbedingungen von entscheidender Bedeutung ist.

Anwendungen von Rohren mit HDPE-Stahlrahmen

- Industrielle Anwendungen: Ideal für den Transport von abrasiven Materialien in Branchen wie dem Bergbau, bei denen Langlebigkeit und Verschleißfestigkeit entscheidend sind.

- Kommunale Wasser- und Abwassersysteme: Einsatz in Druckwasserversorgungsnetzen und Abwassersystemen aufgrund ihrer hohen Festigkeit und Korrosionsbeständigkeit.

- Öl- und Gasindustrie: Geeignet für den Transport von Ölen, Gas, und andere Kohlenwasserstoffe, insbesondere dort, wo eine Kombination aus Festigkeit und chemischer Beständigkeit erforderlich ist.

- Marine- und Unterwasser-Pipelines: Durch ihre Beständigkeit gegen Korrosion und hohen Druck eignen sie sich für Unterwasser-Pipelines und Marineanwendungen.

- Landwirtschaftliche Bewässerung: Die Rohre’ Durch ihre Langlebigkeit eignen sie sich für großflächige Bewässerungssysteme, insbesondere in Gebieten mit rauen Umgebungsbedingungen.

Produktbeschreibung

| Produktname | PE100 HDPE-Rohr für die Wasserversorgung |

| Material | Ppolyethylen mit hoher Dichte |

| Norm | GB / T13663-2000, ISO (Englisch) 4427-1:2007 |

| Spezifikation | DN20-DN1200 |

| Druck | 11,13,6,17,21,26 SZR11,13,17,26 |

| Länge | 6 Messgeräte oder nach Bedarf, DN20-DN63 kann Spulen herstellen |

| Hauptanwendung | Wasserversorgung und -ableitung |

| Druck | PN0,6 MPa | PN0,8 MPa | PM1,0 MPa | PN1,25 MPa | PN1,6 MPa |

| Äußere Durchmesser (Mm) |

Dicke (Mm) |

Dicke (Mm) |

Dicke (Mm) |

Dicke (Mm) |

Dicke (Mm) |

| 20 | 2.3 | ||||

| 25 | 2.3 | ||||

| 32 | 3.0 | ||||

| 40 | 3.7 | ||||

| 50 | 4.6 | ||||

| 63 | 4.7 | 5.8 | |||

| 75 | 4.5 | 5.6 | 6.8 | ||

| 90 | 4.3 | 5.4 | 6.7 | 8.2 | |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

| 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

| 630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

| 710 | 27.2 | 33.9 | 42.1 | 52.2 | |

| 800 | 30.6 | 38.1 | 47.4 | 58.8 | |

| 900 | 34.4 | 42.9 | 53.3 | ||

| 1000 | 38.2 | 47.7 | 59.3 | ||

| 1200 | 45.9 | 57.2 |

Zhongtong HDPE PIPE System Professioneller Lieferant

Zhongtong HDPE PIPE System Professioneller Lieferant