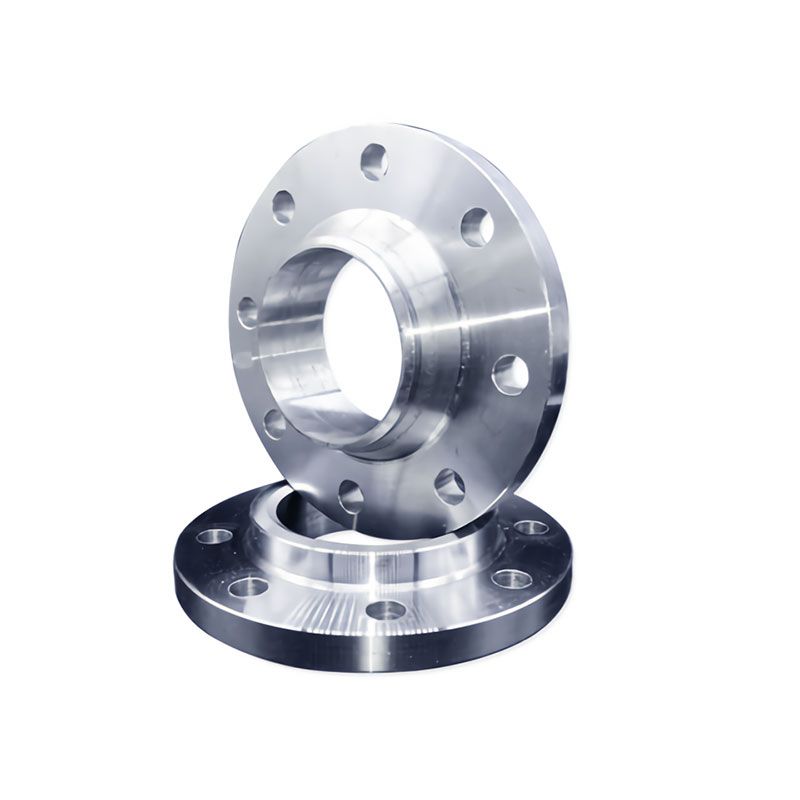

Flanges serve as critical components in various industrial applications, playing a pivotal role in connecting pipes, valves, and other equipment.

Performance of Flanges

- Connection and Sealing: Flanges provide a secure connection between pipes or other equipment, ensuring a tight seal that prevents leaks and maintains system integrity.

- Versatility in Design: Available in various designs, such as slip-on, weld neck, and blind flanges, allowing for adaptability to different piping systems and applications.

- Material Diversity: Constructed from materials like stainless steel, Kohlenstoffstahl, and alloy steel, offering options that cater to specific requirements such as corrosion resistance and high-temperature applications.

- Pressure Resistance: Engineered to withstand high pressures, making them suitable for applications ranging from low to high-pressure systems.

- Facilitates Maintenance: The use of flanges simplifies maintenance and repair activities, as they enable easy disassembly and reassembly of components in a system.

Applications of Flanges

- Pipeline Systems: Essential in oil and gas pipelines, water supply networks, and chemical processing plants, ensuring secure connections between pipeline components.

- Power Generation: Used in power plants to connect pipes and valves in steam and water systems, contributing to the efficiency and reliability of power generation.

- Chemical Processing: Widely applied in chemical industries for connecting pipes carrying corrosive substances, with flange materials chosen for their chemical resistance.

- Shipbuilding: In ship construction, flanges play a crucial role in connecting pipes and equipment, ensuring the integrity of various systems on board.

- Construction and Infrastructure: Utilized in construction projects for connecting structural components, providing stability and facilitating disassembly when necessary.

Produktbeschreibung

|

Steel steel flanges

|

||

|

Material

|

Carbon steel

|

ASTM A105. ASTM A350 LF1. LF2, CL1/CL2, A234, S235JRG2, P245GH

|

|

P250GH, P280GHM 16MN, 20MN ,20#

|

||

|

Stainless steel

|

ASTM A182, F304/304L, F316/316L

|

|

|

Alloy steel

|

ASTM A182 A182 F12,F11,F22,F5,F9,F91etc.

|

|

|

Norm

|

ANSI

|

Klasse 150 steel flanges-Class 2500 steel flanges

|

|

DIN

|

6Bar 10Bar 16Bar 25Bar 40Bar

|

|

|

JIS

|

5K steel flanges-20K steel flanges

|

|

|

UNI

|

6Bar 10Bar 16Bar 25Bar 40Bar

|

|

|

EN

|

6Bar 10Bar 16Bar 25Bar 40Bar

|

|

|

TYPE

|

1.Welding neck steel flange 2.Slip on

|

|

|

3.Blind flange 4.Long welding neck flange

|

||

|

5.Lap joint flange 6.Socket welding

|

||

|

7.Threaded flange 8.Flat flange

|

||

|

Surface

|

Anti-rust oil, clear lacquer, Black lacquer, Yellow lacquer,hot-dipped Galvanized,electrical galvanized

|

|

|

Verbindung

|

Schweißen, Threaded

|

|

|

Technical

|

Forged, Guss

|

|

|

Größe

|

DN10-DN3600

|

|

|

Package

|

1.>Standard export packaging (Plywood Case Of Outside,Plastic Cloth Of Inside). 2:As Customers’ Requirements

|

|

|

Heat Treatment

|

Normalizing, Annealing, Quenching Tempering

|

|

|

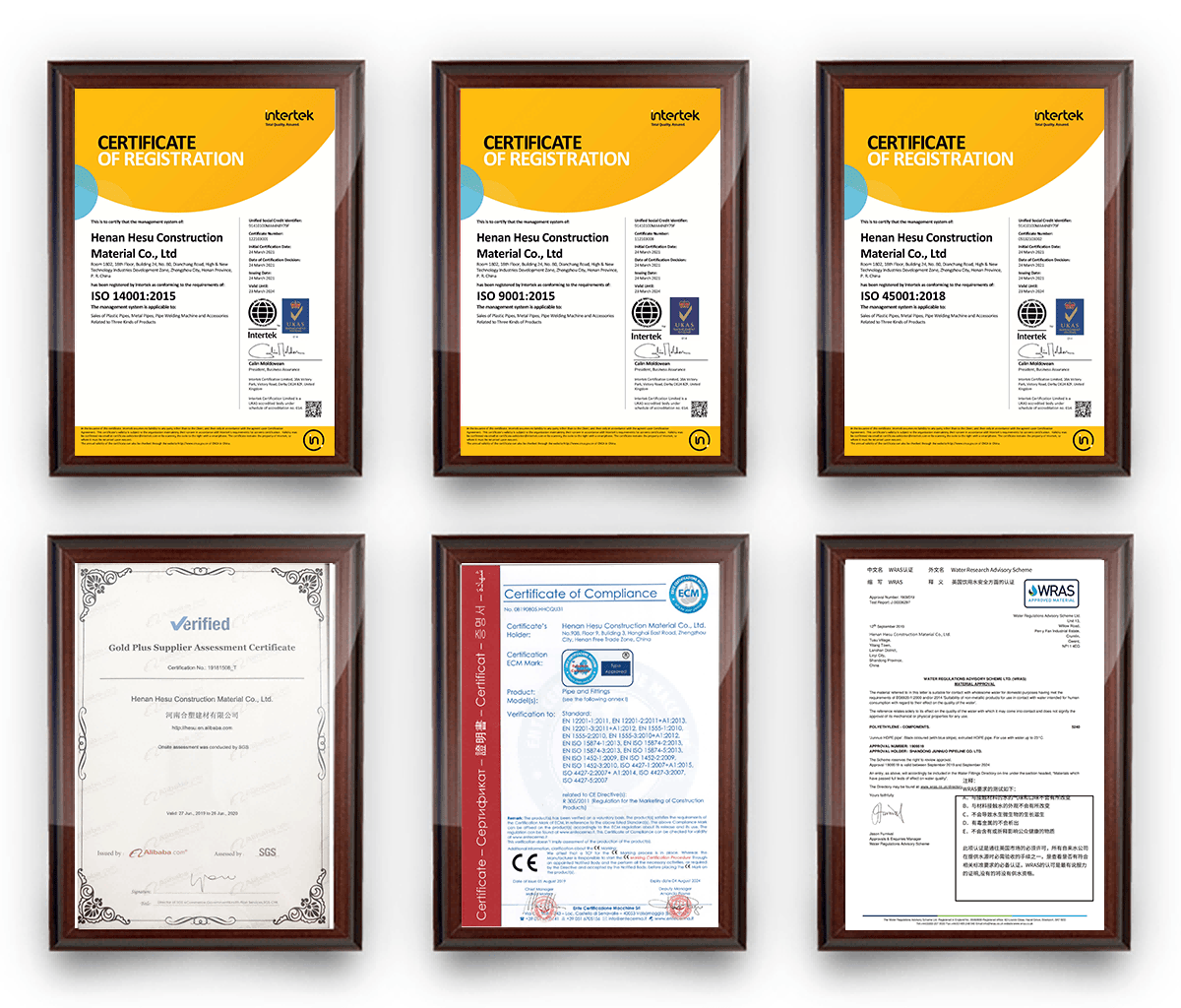

Zertifikat

|

TUV,ISO9001:2008;PED97/23/EC,ISO14001:2004,OHSAS18001:2007

|

|

|

Applications

|

Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry,and general pipes connecting

projects etc. |

|

Zhongtong HDPE PIPE System Professioneller Lieferant

Zhongtong HDPE PIPE System Professioneller Lieferant